Injection Moulding |

Posted: December 16, 2022 |

Injection Moulding: Best Practices and BenefitsOne of the most often used processes for making plastic goods is this one. As an example, imagine that you own a manufacturing business and need to produce a lot of identical-sized plastic goods in a short amount of time. Then you may make your items more quickly than ever before using plastic injection molding. The nicest part about it is how cheap it is and how little staff supervision is needed for this molding.

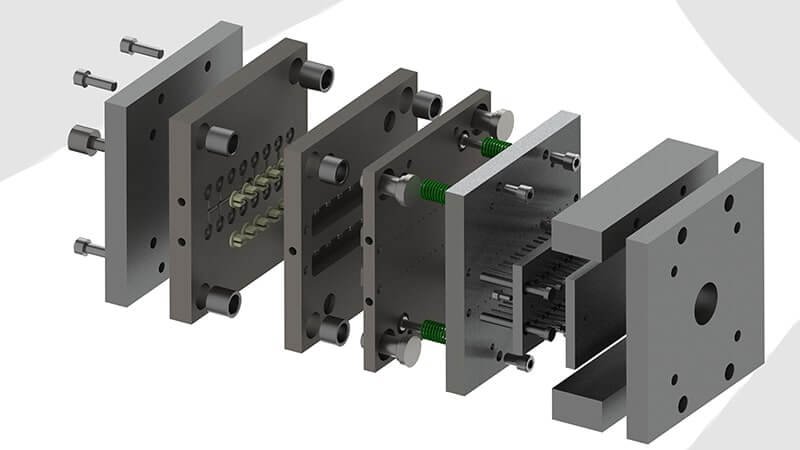

A machine for injection molding operates in many steps. The provided plastic is melted in the first step, and the melted plastic is then put into a machine that makes molds. Then, the components of that mold machine are compressed together to form the shape of your plastic product. The chilling step is the next. Here, your created plastic goods will all be cooled by the molding machine. These days, a lot of people use this kind of molding to produce their goods more quickly, and injection molding is also more exact. Since the moulding machine's components are entirely computerized, your job will go more smoothly and accurately as a result. Products made of plastic that are handmade sometimes go wrong and may be a nightmare. Products created via injection molding are always superior than those made of plastic by hand. These days, the majority of auto manufacturing businesses make extensive use of injection molding. The radiator cover for your automobile, for instance, will be produced with the help of this technology. This kind of procedure is necessary to ensure accuracy and speed since millions of automobiles are produced each year all around the globe. For additional details on our services relating to injection moulding, please visit the website of this UK plastic manufacturer. Several design principles:Here are 5 other design strategies:

Plastic injection molding has many benefits.

These are a few design recommendations and benefits of injection molding.

|

|||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||